See what we showed at MACH, in your own environment

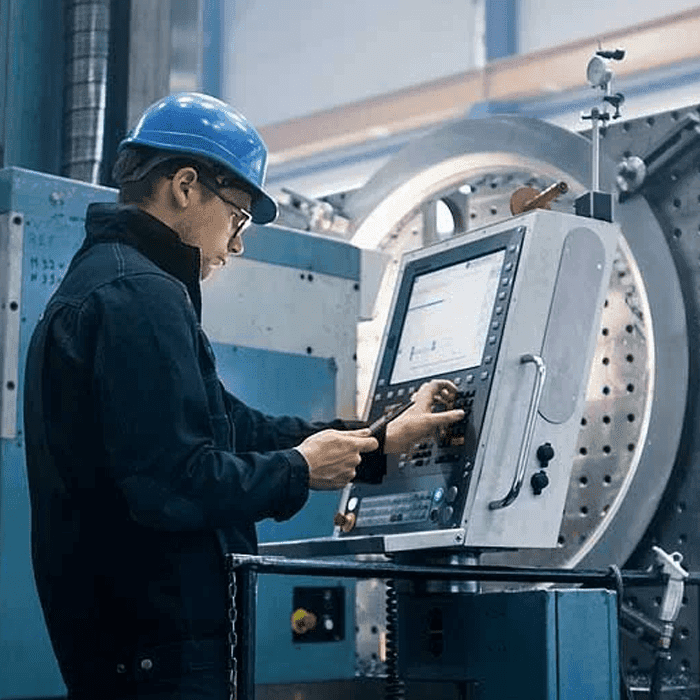

We’ll walk through your processes, challenges, and opportunities using real manufacturing scenarios. DynamxMFG is an execution platform for SME manufacturers, giving you real-time visibility of people, machines, and orders, so you can fix problems while the shift is still running.

Refresh yourself with a tour of DynamxMFG

Experience the platform that puts control in your hands.

Step 1: Take our Digital Readiness Assessment

Quickly evaluate how prepared your operations are for digital transformation. Answer a few focused questions to identify gaps, opportunities, and the next practical steps toward better visibility, control, and performance across your manufacturing processes.

Step 2: Calculate your Savings & ROI with DynamxMFG

See the financial impact of improving visibility and control across your operations. Use real production data to estimate potential cost savings, efficiency gains, and return on investment from digitising your shop floor.

Step 3: Book a Discovery Call

Speak with a trusted member of our team to explore your current challenges, priorities, and opportunities. We’ll map what this could look like in your environment and outline practical next steps tailored to your operations.

See what other manufacturers are saying

Success stories from teams who transformed their factories with DynamxMFG.

DynamxMFG is an excellent choice for manufacturers looking to digitise operations without being overwhelmed by complexity.

Kristopher S

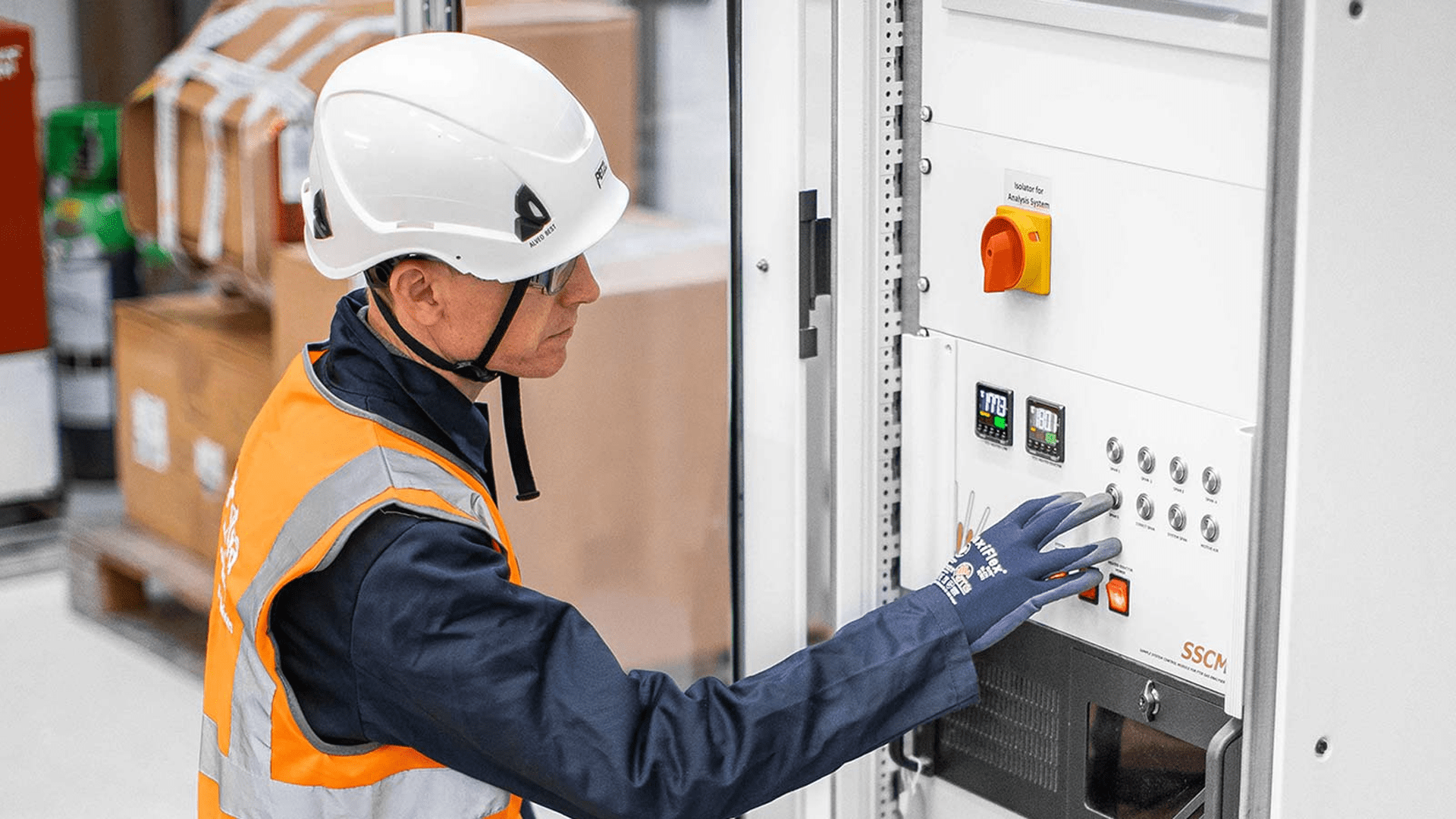

Service Engineer at Protea

As GMC has grown, it had become harder for me to have such a keen view on components to see if those parts were profitable or not. DynamxMFG enabled us to monitor the machine time and see whether we’re making a profit or a loss on each component.

Paul B

Managing Director at GMC

DynamxMFG has significantly eased our start-up growing pains. We've really enjoyed working with the team and see huge potential in the software to support our growth as we scale.

Liam M

Head of Operations at Maeving

DynamxMFG is an excellent choice for manufacturers looking to digitise operations without being overwhelmed by complexity.

Kristopher S

Service Engineer at Protea

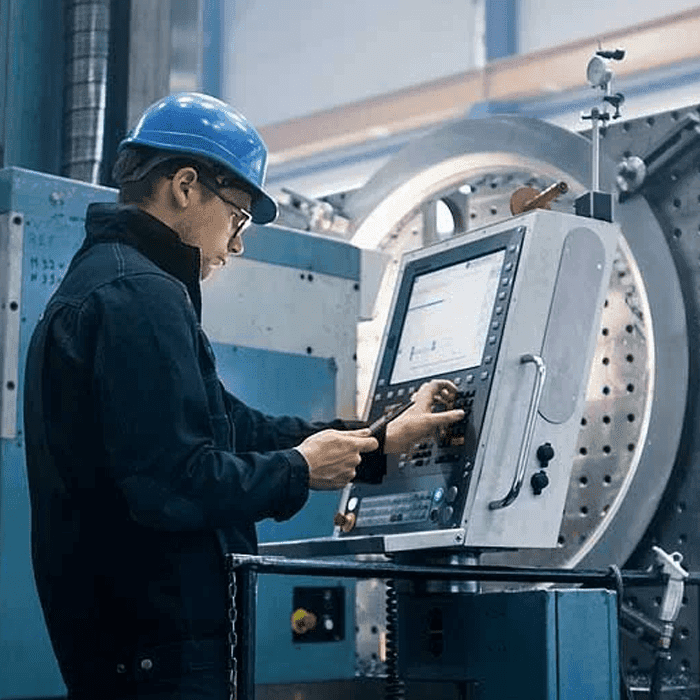

As GMC has grown, it had become harder for me to have such a keen view on components to see if those parts were profitable or not. DynamxMFG enabled us to monitor the machine time and see whether we’re making a profit or a loss on each component.

Paul B

Managing Director at GMC

The ability to dynamically modify BOMs after release, adding or removing items from work orders, scrapping, and reworking parts, has been the single biggest improvement for our business.

Andrew T

Managing Director at Protea

Overall, our experience has been very positive, with helpful and knowledgeable staff who work closely with us through regular meetings to tailor the software to our needs.

Michael G

Systems Engineer at Scintam Engineering

Setting up DynamxMFG was quick, support from the technical team was readily available when needed, the system is easy to use, and it offers excellent value for money compared to other solutions.

Liam Moriarty

Head of Operations at Maeving

The ability to dynamically modify BOMs after release, adding or removing items from work orders, scrapping, and reworking parts, has been the single biggest improvement for our business.

Andrew T

Managing Director at Protea

Overall, our experience has been very positive, with helpful and knowledgeable staff who work closely with us through regular meetings to tailor the software to our needs.

Michael G

Systems Engineer at Scintam Engineering

DynamxMFG bridges the gap between high-end MES systems and the practical needs of growing manufacturers, providing a live view of production that gives immediate insight into work orders, progress, bottlenecks, and downtime so issues can be identified and resolved before they escalate.

Kristopher S

Service Engineer at Protea

With DynamxMFG, all our production processes are tracked, and the relevant data is captured. This increases our control over the business and helps us identify more opportunities to enhance efficiency and quality.

Neil S

Operations Director at QK-TEX

Our experience has been positive, and it was definitely worth switching. The support we have received has been extremely helpful. My favourite feature is the integration & automation capabilities. The possibilities are endless.

Philippos F

Head of Digital Transformation at CPL

DynamxMFG bridges the gap between high-end MES systems and the practical needs of growing manufacturers, providing a live view of production that gives immediate insight into work orders, progress, bottlenecks, and downtime so issues can be identified and resolved before they escalate.

Kristopher S

Service Engineer at Protea

With DynamxMFG, all our production processes are tracked, and the relevant data is captured. This increases our control over the business and helps us identify more opportunities to enhance efficiency and quality.

Neil S

Operations Director at QK-TEX

You’ve seen what’s possible, now make it happen

You’ve explored the software and taken the first step. Don’t let the momentum stop here. Take the next move toward better visibility, stronger control, and more confident decisions across your operations.