Cumberland Platforms LTD (CPL) is one of the UK’s leading manufacturers of vehicle-mounted access platforms for utilities, telecoms, and maintenance sectors. As part of the KLUBB Group, CPL delivers over 700 vehicle conversions per year from their Kettering site, ranging from pickup-mounted and van-mounted platforms to tracked and truck-mounted systems. CPL also provides nationwide servicing, maintenance, and spare parts, supporting both its own and third-party platforms, establishing a strong presence in the UK access-equipment market.

“What used to rely on duplication, manual handovers, and constant checking now flows seamlessly from our configurator to our CRM and through to our ERP. Enter information once, and the data takes care of the rest.”

Philippos, Head of Digital Transformation

The Challenge

CPL was operating across multiple disconnected systems that could not scale with their rapid growth. Without unified data flowing through production, the team were faced with:

- Multiple disconnected systems: Information lived in several separate tools, forcing teams to manually transfer or re-enter data. This created inconsistencies, duplicated effort, and made it difficult to maintain a single source of truth across production.

- Bottlenecks between kitting and production: Because kitting and production teams lacked real-time visibility of each other’s progress, materials were not always ready when needed. This misalignment caused delays, confusion, and frequent stops on the shop floor.

- Inability to plan production against resources: Without a unified view of workloads, capacity, and material availability, managers struggled to schedule builds accurately. Resource planning became reactive, making it harder to keep up with rising production volumes.

- Production delays from bottlenecks: With limited visibility and inconsistent data, small issues escalated quickly. Delays in kitting, missing information, or miscommunication often resulted in stalled jobs and extended lead times.

These challenges made it increasingly difficult for CPL to maintain efficiency, scale operations, and deliver builds on time, prompting the search for a more connected, scalable production system.

What made DynamxMFG the right fit?

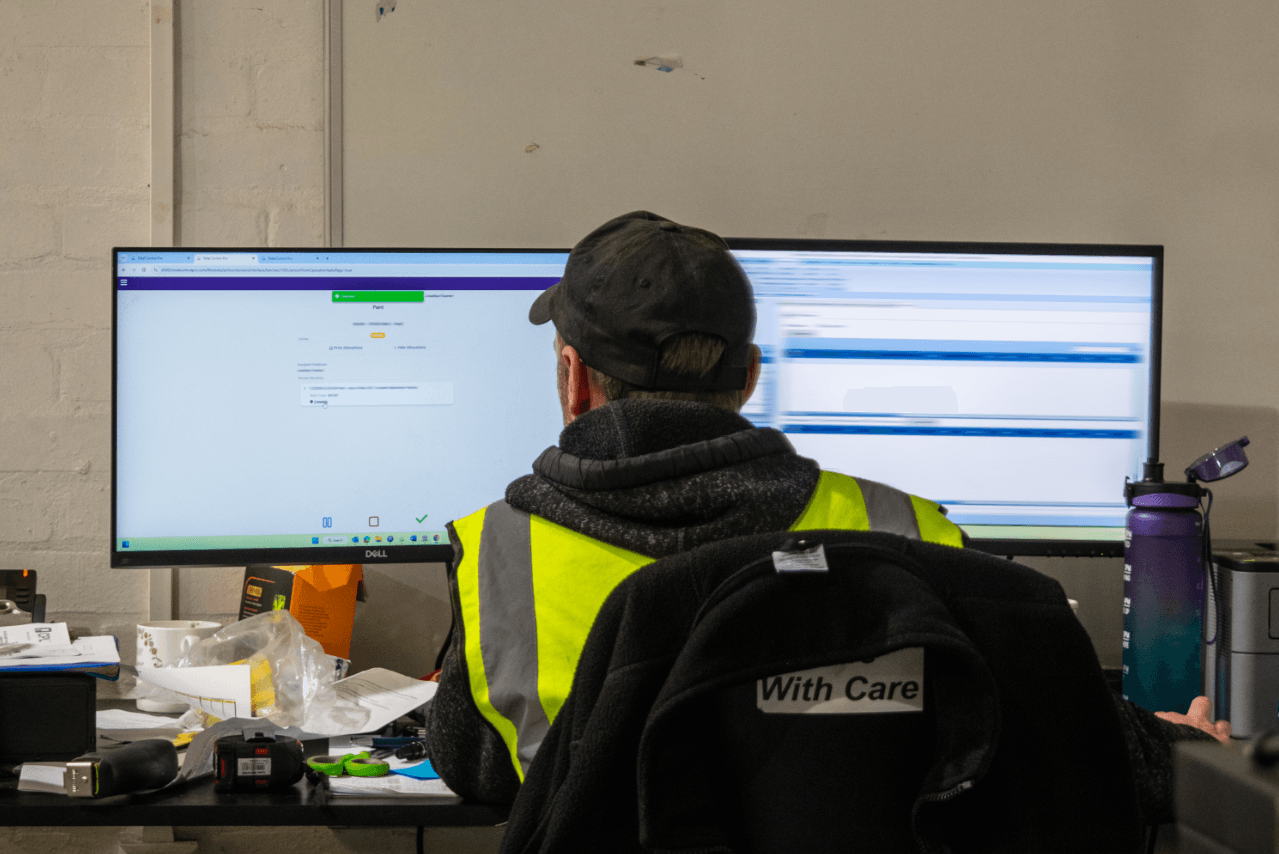

CPL adopted DynamxMFG in early 2024 to connect and streamline their production management. They began with a proof of concept but soon realised that DynamxMFG was the answer they had been searching for and began the full deployment. DynamxMFG provided CPL with:

- Flexible BOM management: CPL builds highly customised vehicle-mounted platforms, so fast and accurate engineering updates are essential, and have become far easier with DynamxMFG.

- Real-time production tracking: Managers no longer have to chase information or wait for updates, they can see issues immediately and act before delays escalate.

- Scalable with growth and multi-site operations: Their build volume and workforce keep expanding, and DynamxMFG can expand with them.

The Impact

CPL achieved clearer, faster, and more connected production workflows, improved visibility, and significantly reduced manual workload, while gaining confidence in a system that evolves with their needs. Since implementing DynamxMFG, CPL have:

- Reduced admin & manual data entry by 75%

- Achieved an OTD (On Time Delivery) rate of 99.9%

- Increased production efficiency by 12%

“DynamxMFG is very easy to use, managing BOM & process changes is a breeze and saves so much time. Our experience has been positive, and it was definitely worth switching. The support we have received has been extremely helpful. We still have more features requested, and the team has already been working on them, so we are really looking forward to those.”

Philippos, Head of Digital Transformation

Looking Ahead

With DynamxMFG now embedded at the heart of production, CPL is focused on building a fully connected technology stack that supports both its UK operation and European plants. By standardising processes and data across sites, CPL will be able to scale output without adding unnecessary complexity or administrative overhead.

The team is also accelerating the rollout of new product configurations. With flexible BOM management and controlled change processes in place, engineering updates can move from design to the shop floor faster and with greater confidence, supporting CPL’s highly customised build model.

As production volumes continue to grow, CPL plans to further leverage real-time data to improve planning accuracy, reduce bottlenecks before they impact delivery, and maintain consistent build quality across an expanding operation. DynamxMFG provides the foundation for this next phase of growth, giving CPL the visibility, control, and scalability needed to support long-term expansion.