Protea

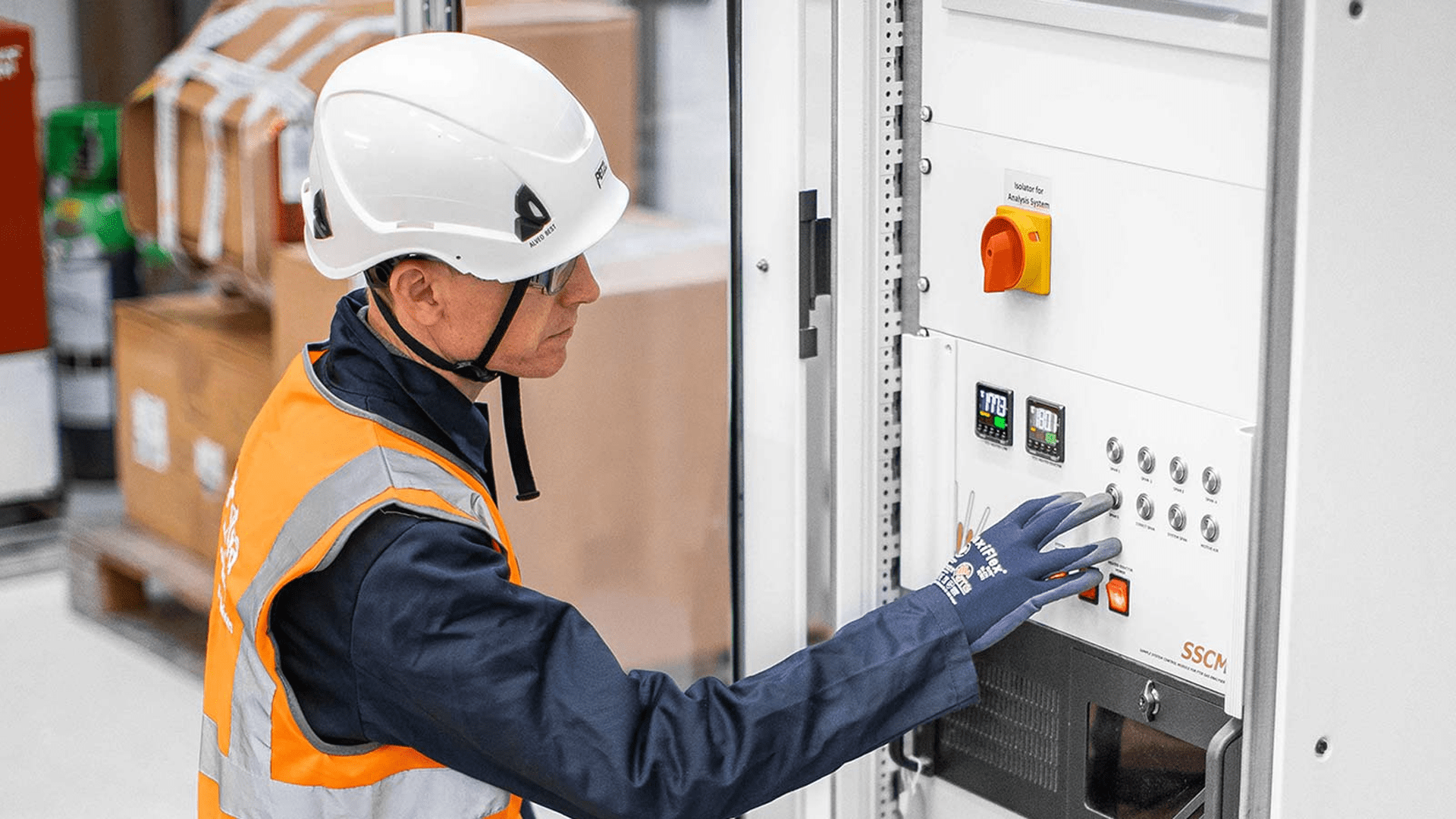

Protea is a global manufacturer of gas analysers for the oil and gas industry.

Case Study: Protea

Protea manufactures high-precision gas analysers, serving the oil and gas industry with cutting-edge technology. Every analyser is built to exact specifications, ensuring accuracy and reliability. With component-level traceability and serialisation being critical, Protea required a solution that could provide full audit capabilities while allowing flexibility in production.

THE CHALLENGE

Like many manufacturers, Protea faced a common trade-off between maintaining high productivity and ensuring complete traceability of every component. They needed a smart solution that would not only track every part in detail but also allow real-time flexibility during production.

THE SOLUTION

To address these challenges, Protea implemented DynamxMFG, our powerful, smart manufacturing platform, which allowed them to:

✅ Enable detailed component-level traceability

✅ Allow dynamic modifications to Bills of Materials (BOMs) post-release

✅ Facilitate efficient scrapping and reworking of parts

✅ Ensure data integrity while keeping production agile and adaptable

“The ability to dynamically modify BOMs after release – adding or removing items from work orders, scrapping, and reworking parts – has been the single biggest improvement for our business”

Andrew Toy, Managing Director

THE OUTCOME

With DynamxMFG, Protea has achieved:

✅ Full audit trails at a production level

✅ Enhanced production insights through the Smart Manufacturing Hub’s analytics dashboard

✅ Optimised production management, improving efficiency and adaptability

Want to hear more about DynamxMFG? Fill out the form below and we’ll get in touch!