Over the years, supply chains have grown in intricacy and complexity with many plants and suppliers are being spread out across the world. Building resilience within your supply chain to ensure it can withstand external shocks has never been more important. Sometimes external shocks can be anticipated, and you have chance to prepare, like with Brexit. But sometimes they are forced upon with little-to-no notice at all. When COVID-19 hit, it came as no surprise that national lockdowns impacted these complex manufacturing supply chains, pushing resilience to the limit.

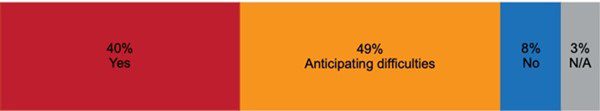

At the start of the UK’s first national lockdown, Make UK’s YouGov survey showed that manufacturers were having difficulties sourcing component parts directly from China or any other countries affected by Coronavirus. Like with any linear chain of dependents, it was only a matter of time before this would have a knock-on effect to production in the UK.

Source: Make UK YouGov survey of 244 manufacturers between 4th – 16th March 2020

How COVID-19 impacted manufacturing supply chains

Component parts were being held up around the globe causing many production facilities to come to a halt. During this time, the cost of getting these parts to the UK also significantly increased and only extended the delays. For many, the pandemic has exposed opportunities to improve operations, processes, and logistics, but is COVID-19 the driver of change that will instil agility and resilience to the sector?

According to The Manufacturer’s Digital Transformation Assessment 2021, manufacturer priorities have largely stayed the same despite COVID-19 struggles with 75% of them wanting to prioritise supply chain integrity and resilience. The report also shows that the pandemic has influenced their decision to invest in adopting digital technologies with 67% of them accelerating their plans adoption projects.

Linear Chains vs Chain Networks

The traditional linear supply chain is rapidly transforming into a series of dynamic, integrated systems. In a traditional manufacturing supply chain, information moves like falling dominos – with each step dependant on the one before it. Whereas in a supply chain network, information is being passed fluidly between a series of manufacturers and suppliers, all of which are being informed based on real-time data. A supply chain network reflects the complexity of manufacturing processes across all industries. Parts and components are often sourced from across the world, modified and adapted before being sent on to someone else for the next part of the manufacturing process, crossing the paths of different sectors, companies and even countries.

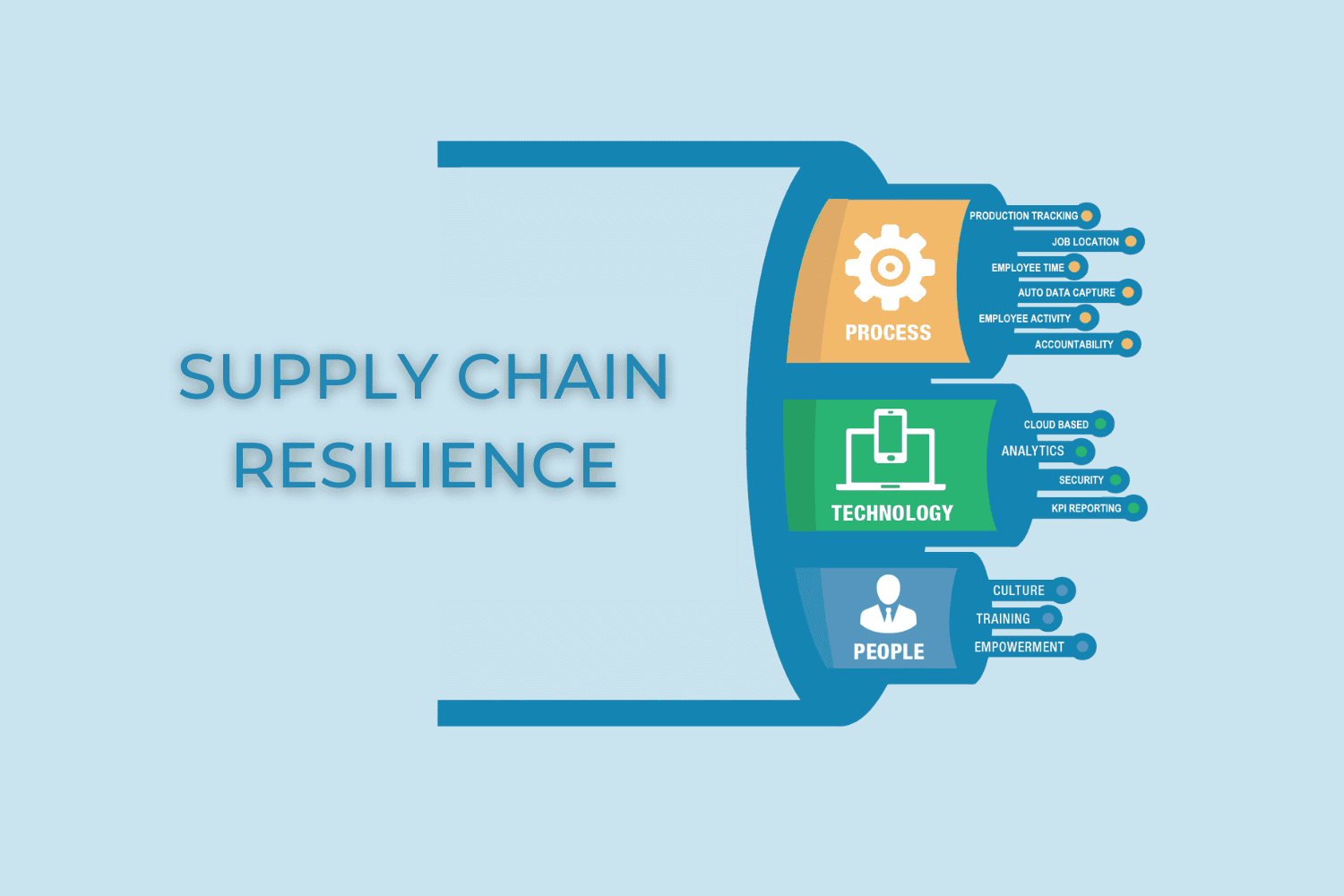

How to build manufacturing supply chain resilience

Building a smart supply chain network can be challenging but there a number of ways to make it much simpler.

- Understand the supply network by increasing visibility

End-to-end visibility allows you to view multiple aspects of the supply chain all at once, providing insights into critical areas. Instead of viewing siloed batches of information from various sources and attempting to piece them together manually digital technologies enable companies to track material flow, synchronise schedules and balance supply and demand. Once you have completely understood your position within the supply chain network you need to understand how the links fit together.

- Mitigate risk

Brexit has forced UK businesses to prepare their supply chains for a drastic change. It encouraged people to make their supply chains more resilient through planning. Risks that would impact businesses were considered and solutions were found before the UK left the EU, minimising the potential for disruption. This goes to show that getting ahead of the game is crucial. Manufacturers that had assessed the risks impacting their supply chain and planned for external shocks would have found it much easier to battle lockdown measures than those who hadn’t planned for disruption in the global supply chain. Once you gain complete visibility and understand how your supply chain works, you can identify where a problem might occur and plan a solution that ensures you are not impacted.

- Diversification and Localisation

Naturally, the first thing that comes to mind for many when thinking about strengthening supply chains, is reshoring. However, when a selection of manufacturers came together at the Backing Britain event last August, many mentioned that whilst they have the desire to reshore – it is not a practical strategy that they could commit to. As a solution to this, the idea of ‘nearshoring’ was discussed, where nearby suppliers are used, sitting in the middle of offshoring and reshoring.

Diversifying your supply base will ensure that there is always a back-up supplier for when things go wrong. Utilising multiple suppliers in multiple locations will help to build supply chain resilience. By combining local suppliers with existing global supply chains you can ensure you don’t end up with a shortage of critical components and prevent your operations coming to a halt.

Build strong relationships with your suppliers just as you would with your customers. Opening lines of communication between everyone involved in your supply chain network will allow for suppliers, and partners to share data and information directly to enable decisions to be made based on coherent data. How can you work together to reduce lead-times? Is the information you’re sharing accurate, valuable and relevant?

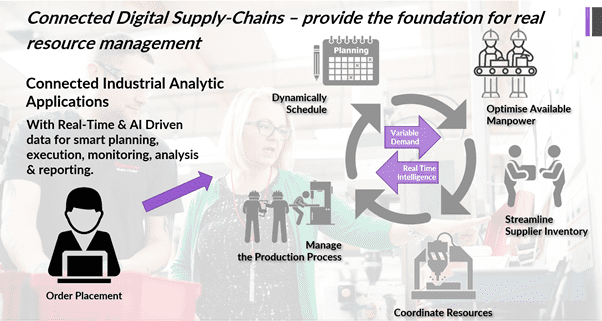

- Going Digital

Data is critical for establishing the foundations of a resilient supply chain and technology is crucial to gathering accurate data. Digital supply chains can help you improve your supplier selection, manage relationships and provide real-time analysis that will increase agility and predict future shocks. Once digitised, it becomes much easier to connect and coordinate resources to dynamically schedule to order. Not only will this connectivity benefit internal systems but it’ll also enable better collaboration between OEMs and SME manufacturers to fill the gaps and manage out processes.

What does a digital supply chain look like?

Let’s take a look at JCB who recently won a £26 million order from Ardent Hire Solutions, and consider how a digital supply chain could work for them. For JCB to coordinate all the parts needed to create their 525 new telehandlers they need to work with their suppliers in a dynamic and effective way. They need to reach out to their many suppliers, to ensure they’re getting the right resources at the right time. The task for JCB to manage all the parts coming in is a very difficult and manual process which can be made much simpler by using connected digital technologies like the TotalControlPro™ Manufacturing Platform.

JCB’s manufacturing suppliers could make use of the Customer Management and Inventory modules to create sales orders determined by their current level of stock and even create a order with their OEM suppliers when their supply is running low, ensuring a continued flow of supply.