From shop floor chaos to real-time control in 90 days

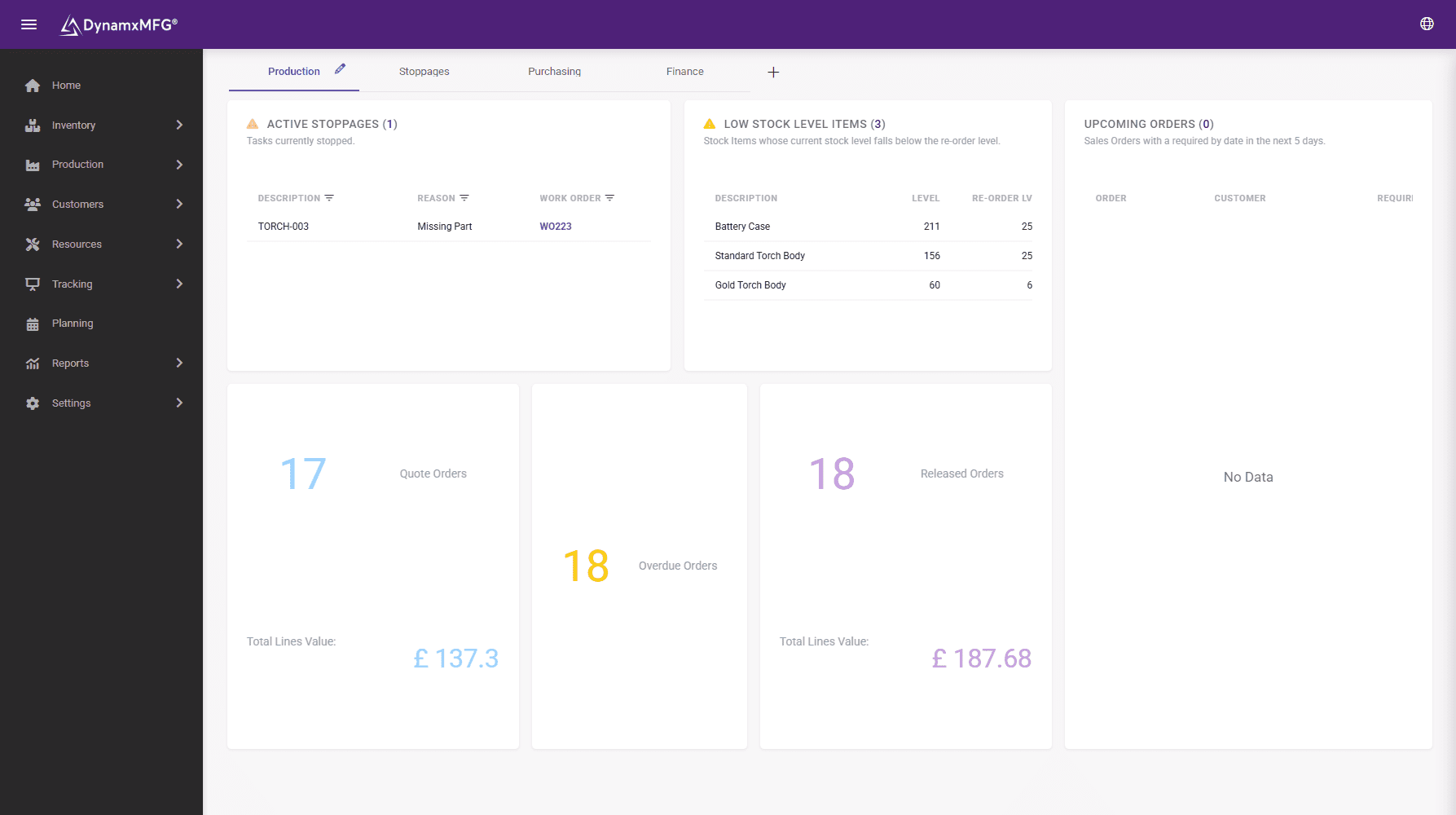

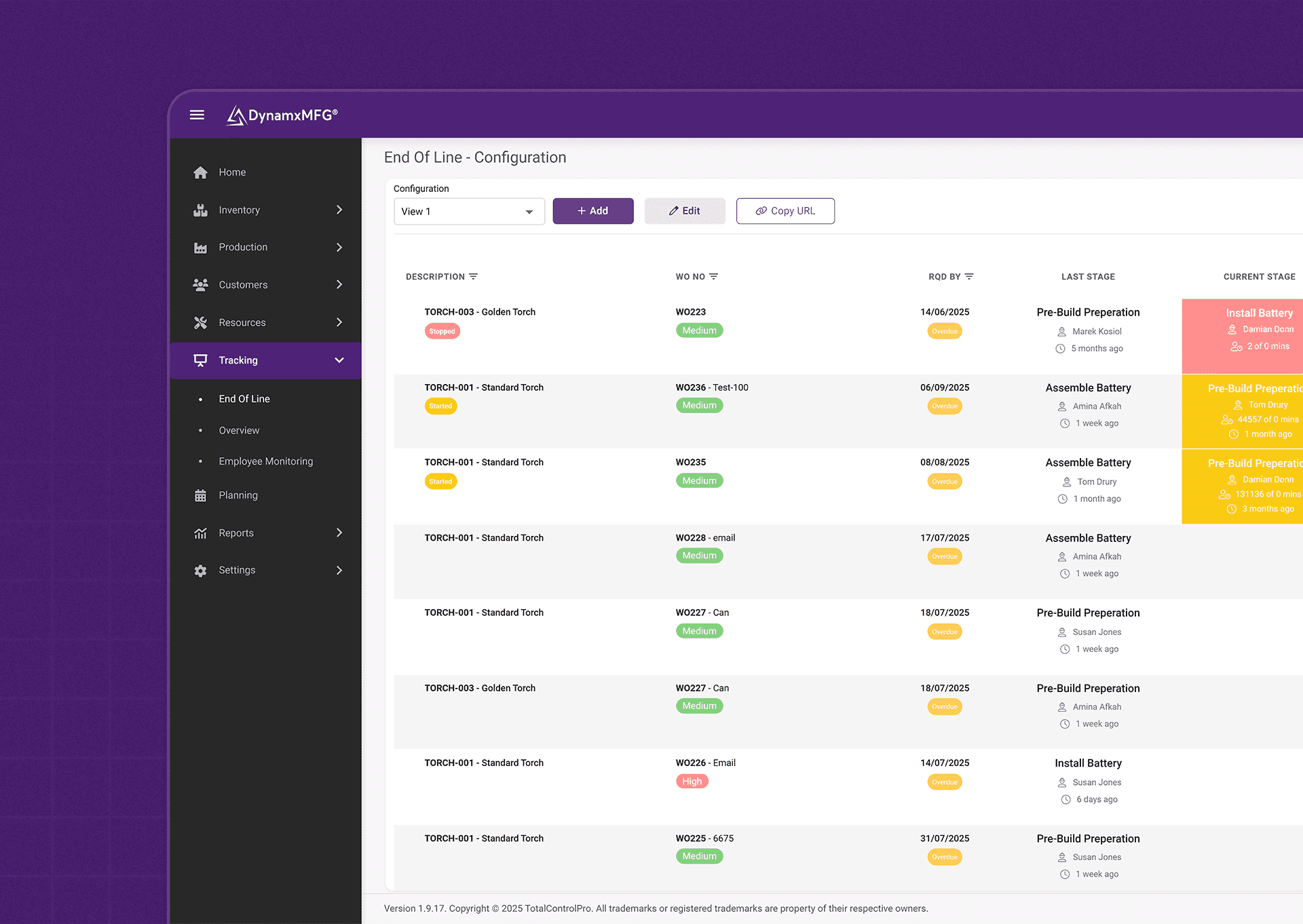

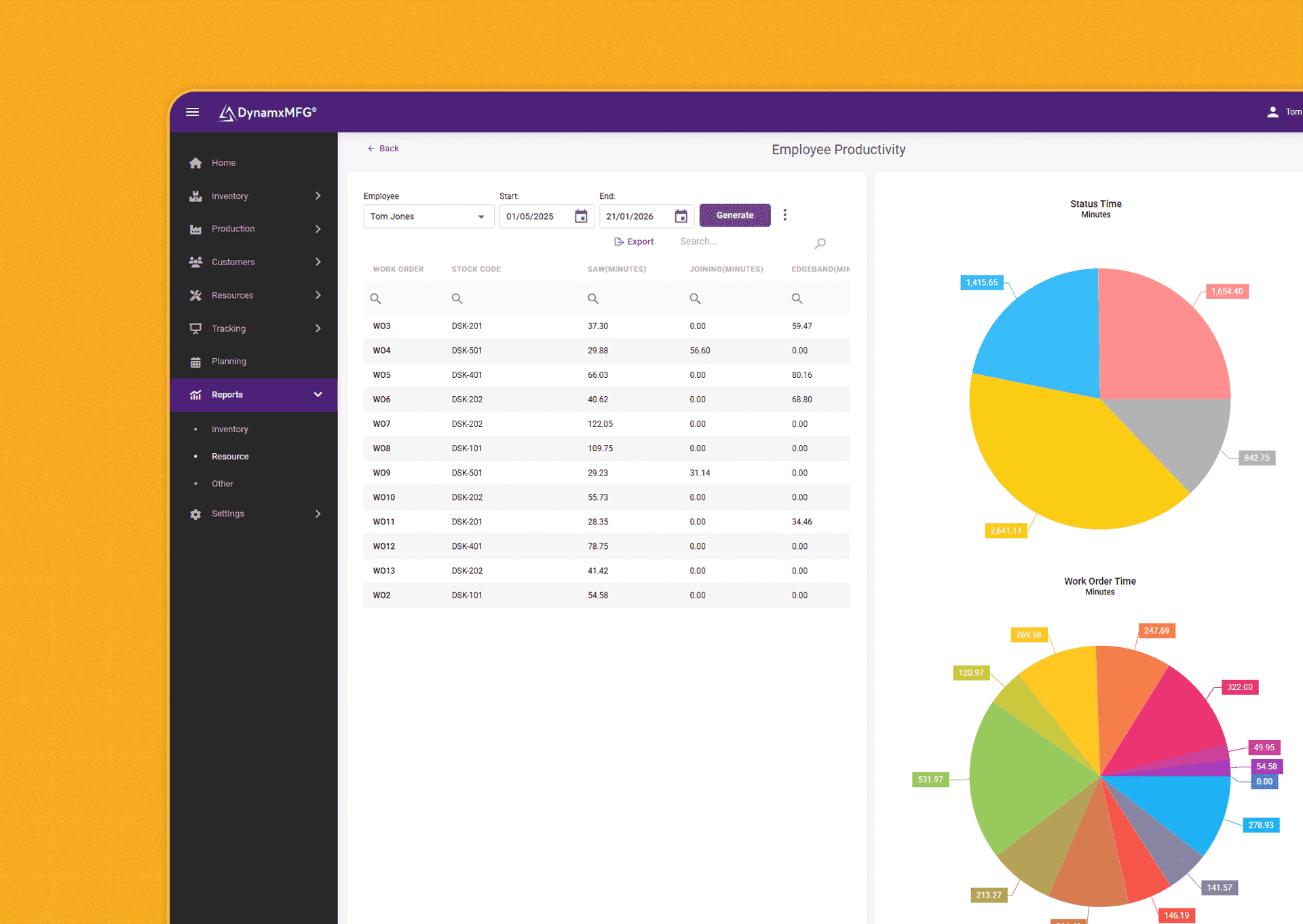

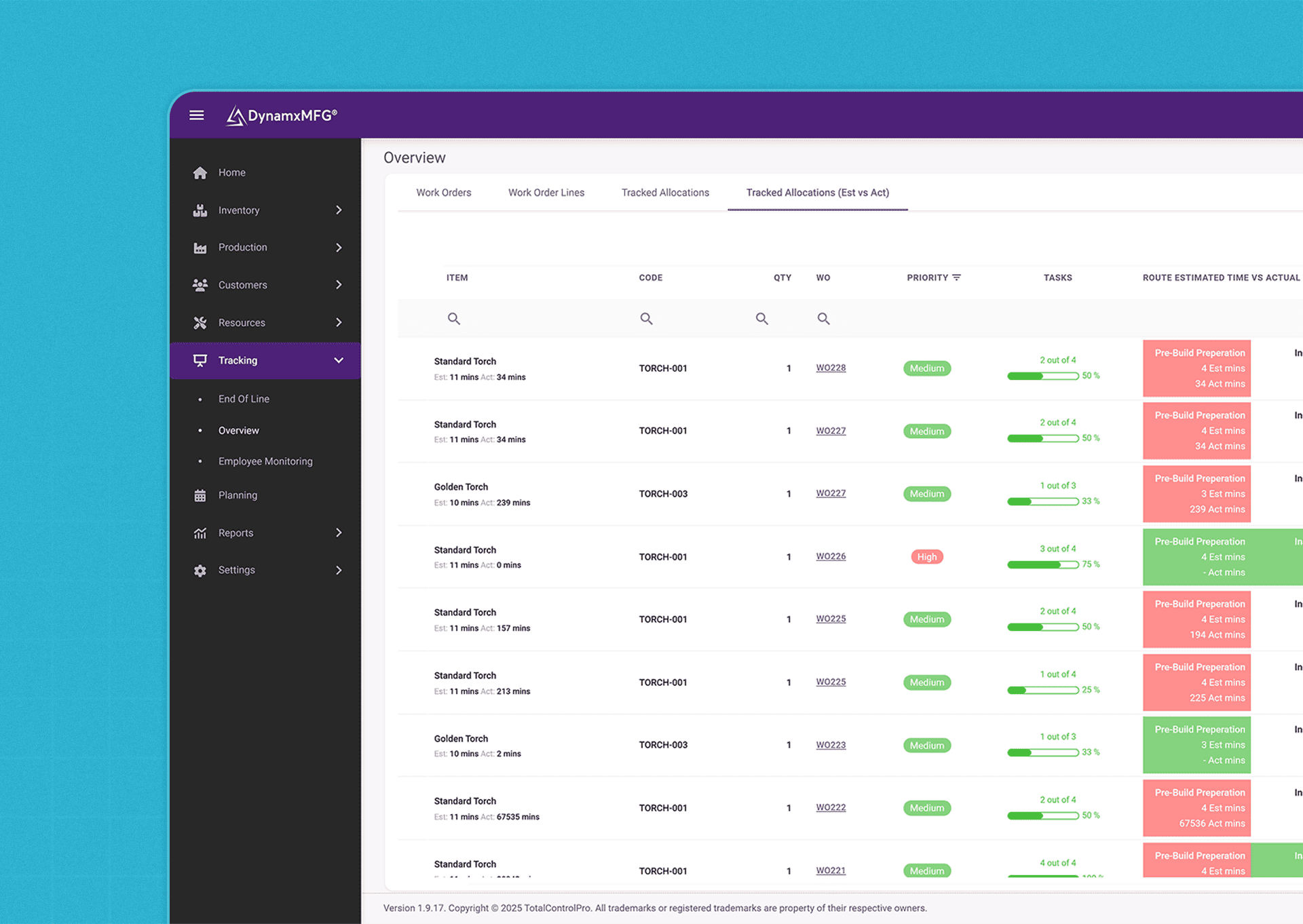

DynamxMFG is an execution platform for SME manufacturers, giving you real-time visibility of people, machines, and orders, so you can fix problems while the shift is still running. DynamxMFG works alongside your ERP and planning tools, not instead of them.

Trusted by leading manufacturers worldwide:

Your manufacturing doesn’t need complex management

DynamxMFG gives you real-time control of your shop floor, so decisions are based on facts, not firefighting.

Start your Digital Readiness check

Discover where your manufacturing operation stands today and get clear, practical steps to accelerate your digital transformation.

What actually changes when execution improves?

Not theory. Not transformation hype.

These case studies show how real factories use DynamxMFG to see what’s happening on the shop floor in real time, and fix problems before they hit delivery or margin.

DynamxMFG users typically experience:

Integrate your existing tech stack

DynamxMFG is designed to connect with the systems you already rely on, creating a single, trusted source of truth across your business. With accurate, up-to-date data shared across your operation, your team spends less time on double data entry and manual checks, and more time focusing on productive, value-adding work. The result is a more connected manufacturing operation, and a system that works around your business, not the other way around.