Manufacturing is already hard enough.

Running the factory shouldn’t be.

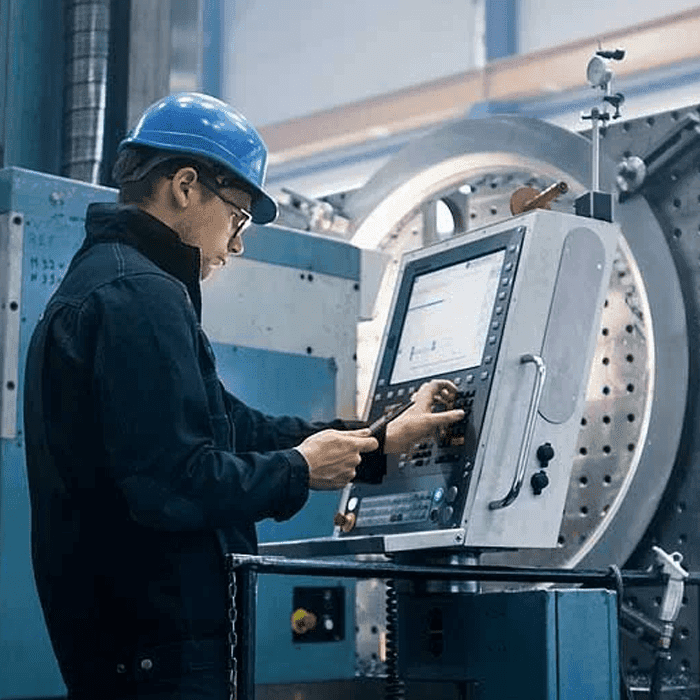

From automated material allocation and real-time work order tracking, to advanced shop floor interfaces and employee clocking, DynamxMFG gives you complete control over production, stock, and reporting, so you can focus on manufacturing, not managing it.

What actually changes when execution improves?

Not theory. Not transformation hype.

These case studies show how real factories use DynamxMFG to see what’s happening on the shop floor in real time, and fix problems before they hit delivery or margin.

DynamxMFG users typically experience:

See what other manufacturers are saying

Success stories from teams who transformed their factories with DynamxMFG.

DynamxMFG is an excellent choice for manufacturers looking to digitise operations without being overwhelmed by complexity.

As GMC has grown, it had become harder for me to have such a keen view on components to see if those parts were profitable or not. DynamxMFG enabled us to monitor the machine time and see whether we’re making a profit or a loss on each component.

DynamxMFG has significantly eased our start-up growing pains. We've really enjoyed working with the team and see huge potential in the software to support our growth as we scale.

DynamxMFG is an excellent choice for manufacturers looking to digitise operations without being overwhelmed by complexity.

As GMC has grown, it had become harder for me to have such a keen view on components to see if those parts were profitable or not. DynamxMFG enabled us to monitor the machine time and see whether we’re making a profit or a loss on each component.

The ability to dynamically modify BOMs after release, adding or removing items from work orders, scrapping, and reworking parts, has been the single biggest improvement for our business.

Overall, our experience has been very positive, with helpful and knowledgeable staff who work closely with us through regular meetings to tailor the software to our needs.

Setting up DynamxMFG was quick, support from the technical team was readily available when needed, the system is easy to use, and it offers excellent value for money compared to other solutions.

The ability to dynamically modify BOMs after release, adding or removing items from work orders, scrapping, and reworking parts, has been the single biggest improvement for our business.

Overall, our experience has been very positive, with helpful and knowledgeable staff who work closely with us through regular meetings to tailor the software to our needs.

DynamxMFG bridges the gap between high-end MES systems and the practical needs of growing manufacturers, providing a live view of production that gives immediate insight into work orders, progress, bottlenecks, and downtime so issues can be identified and resolved before they escalate.

With DynamxMFG, all our production processes are tracked, and the relevant data is captured. This increases our control over the business and helps us identify more opportunities to enhance efficiency and quality.

Our experience has been positive, and it was definitely worth switching. The support we have received has been extremely helpful. My favourite feature is the integration & automation capabilities. The possibilities are endless.

DynamxMFG bridges the gap between high-end MES systems and the practical needs of growing manufacturers, providing a live view of production that gives immediate insight into work orders, progress, bottlenecks, and downtime so issues can be identified and resolved before they escalate.

With DynamxMFG, all our production processes are tracked, and the relevant data is captured. This increases our control over the business and helps us identify more opportunities to enhance efficiency and quality.